Condition-Based Monitoring: Break Free from Unplanned Downtime – Here's How

Ronds Conditon Based Monitoring (CBM) currently has a variety of collection methods that can effectively collect equipment vibration, temperature, impact, oil, electrical and other status data to achieve comprehensive and efficient care of rotating equipment.

Application Deployment

Case stories

CBM systems benefits

Application deployment

Tailored for Industry-Specific Scenarios, RONDS Introduces the “1+N+X” Intelligent Maintenance Solutions

Built on a unified digital platform("1"), the solution integrates diverse intelligent hardware and interfaces("N") to create a unified, full-spectrum data sensing system. This foundation supports a wide range of smart maintenance applications across industries("X"), and is designed for continuous expansion—unlocking limitless potential for digital transformation.

Real Time Vibration Analysis

Ronds intelligent operation and maintenance platform, with "automated equipment inspection, intelligent status judgment, and precise equipment operation and maintenance" as its core content, transforms from the traditional preventive maintenance system to predictive maintenance and predictive maintenance, realizes safe operation of equipment, reduces operation and maintenance costs, improves overall efficiency, improves work experience, and effectively promotes the intelligent transformation of enterprises.

Scenario-based intelligent solutions

Ronds, based on our understanding of the industry and scenario-based algorithm capabilities, addresses various industrial site challenges by building multiple scenario-based intelligent operation and maintenance applications. These solutions are designed with the ability to expand continuously in the future, creating unlimited possibilities and ensuring reliable equipment operation!

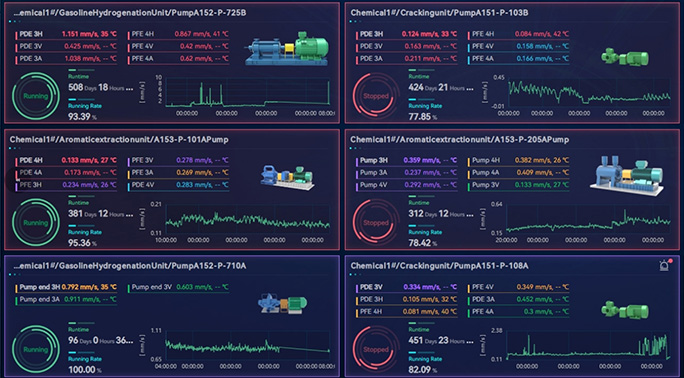

Motor and Pump

In industrial production equipment, pumps are an important component and undertake important work. Since they often have no spare parts, once a failure occurs, it will greatly affect the operation of subsequent equipment. In serious cases, it will lead to production interruptions and accident risks. Routine maintenance of pump equipment is carried out when there is abnormal operation or equipment failure, and manual inspections are used, relying on human experience to judge equipment failures. They are often in a passive maintenance state, which also brings serious safety hazards to production. Ronds's intelligent monitoring solution for pumps can monitor the operating status of pumps in real time, discover potential safety hazards, issue fault warnings in advance, provide enterprises with scientific inspection and maintenance suggestions, improve pump operation efficiency, reduce production costs, and ensure enterprise safety production.

- Difficulty in Inspection - The number of machine pumps is huge, the inspection task is heavy, difficult and inefficient.

- Single Data Collector - The common solutions in the market only measure vibration temperature, without correlating the working conditions and process quantity data. The data is single and has low accuracy.

- Lack of Intelligence - Common wireless sensors on the market lack edge algorithms, are unable to perform data preprocessing and anomaly identification on the hardware side, and have poor timeliness in equipment care.

- Short Battery Life - Common wireless sensors on the market have short battery life and high operation and maintenance costs.

- Integrated Multi-Parameter Monitoring - It integrates the collection of vibration, temperature, and motor operating conditions to realize self-identification of temperature, speed, and start and stop. It combines operating conditions and process quantity data to realize accurate alarm and accurate statistics of start and stop time.

- 100+Indicators Edge Computing - It can realize accurate pointing alarm at the collection end and improve early warning efficiency.

- 20+ Fault Automatic Monitoring - Intelligent alarm and intelligent diagnosis based on a multi-indicator system, covering automatic monitoring of more than 20 faults such as bearings and power frequency.

- Full Wireless Deployment - Full wireless access enables wide-range monitoring coverage of key machine and pump equipment.

Conveyor Belts

As key production equipment for enterprises in industries such as metallurgy, mining, cement, and ports, conveyor belts are always in a long-term, high-load, and complex operating environment. Once equipment failure occurs, it will affect normal production, causing long-term production stoppages and significant economic losses, and may also bring major challenges to production safety. Ronds's intelligent monitoring solution for conveyor belts uses multiple perceptions and sensory integration to achieve unmanned inspections.

- Blind Men Touching an Elephant: Incomplete Coverage - There are many key parts in the conveyor belt, among which the key parts such as rollers and drums currently lack the corresponding technical means to maintain.

- System Independent Information Island - The various belt fault monitoring systems on site are separated from each other, making it impossible to achieve data linkage and comprehensive judgment. The data island phenomenon is serious, and a unified, integrated and intelligent remote care system has not been formed.

- Lack of Monitoring on Wear and Tear - Traditional online monitoring technology has limited capabilities and cannot effectively monitor critical faults such as belt damage and tearing.

- Diversified Data Collector - Through the combination of Lingque intelligent inspection robot + Industrial Smart Eye intelligent real-time video monitoring + vibration temperature monitoring + longitudinal tear monitoring, diversified monitoring such as vibration temperature, video, image, thermal imaging, sound, gas, etc. is formed to comprehensively evaluate the health of the equipment.

- Belt Status Visualization - It intuitively displays equipment health status, real-time monitoring data, alarm classification reminders, equipment status change trends and other key indicators, and supports quick query of equipment history.

- Intelligent Anomaly Identification - Combining various belt conveyor failure case data, we build 50+ intelligent algorithm models, and use intelligent algorithms to quickly and accurately identify abnormal problems such as belt deviation, leakage, tearing, and wear.

- Remote Diagnosis and Maintenance - Abnormalities are automatically pushed, robots quickly review, and the situation is checked remotely. It is also equipped with professional analysis tools such as infrared, temperature, and sound to meet various fault analysis needs.

Low Speed and Heavy Load Equipment

Low-speed and heavy-load equipment exists in various industries and plays a key role in industrial production, such as converters, ladle turntables, rough rolling mills, etc. in the metallurgical industry. The operating status of these equipment directly affects production efficiency and safety. However, due to their complex structure, complex working conditions, low-speed operation, and intermittent motion, monitoring is difficult. In view of the difficulty in monitoring low-speed and heavy-load equipment, Ronds uses a variety of latest colletion hardware such as speed, impact, vibration, temperature, displacement, etc. for comprehensive monitoring, effectively ensuring the reliable operation of low-speed and heavy-load equipment.

- Difficult to Monitor - Some large equipment has complex structure, low speed and heavy load, great impact, high value and difficult maintenance.

- Difficulty in Feature Capture - The equipment is not running continuously or the speed is very low, and the vibration waveform cannot periodically reflect the fault characteristics.

- High Difficulty in Monitoring - Some faults occur at higher frequencies, and traditional vibration sensors cannot capture the corresponding frequencies.

- Integrated Multi-Parameter Monitoring - The industry-leading sensor integrates shock, vibration and temperature data collector, and the monitoring effect is more outstanding.

- Motor Working Condition Linkage - When used in conjunction with motor operating condition sensors, speed-triggered colletion and associated colletion can be achieved.

- Dedicated Shock Analysis - Special impact analysis tool to efficiently analyze the root cause of failure.

- Ultra-Long Time Waveform Collection - The ultra-long time waveform collection capability enables precise fault characteristic capture.

- 24/7 Care - Ronds provides 365*24 hours cloud-based expert support and can provide professional diagnostic services.

Oil Monitoring

80% of the hidden dangers of mechanical equipment come from lubrication and wear failures, which are the main reasons for the failure of large equipment. Oil is the "blood" of mechanical equipment and runs through the entire life cycle of the equipment. It plays an important role in sealing, lubrication, friction reduction, cooling, cleaning, vibration reduction and corrosion prevention in mechanical equipment. Monitoring oil is similar to monitoring human blood, which is important and challenging. Traditional methods such as laboratory analysis and on-site testing still have many shortcomings and pain points. Ronds's intelligent oil monitoring solution provides a correct and effective basis for equipment maintenance and regular inspections through oil status analysis, truly realizing accurate, efficient and convenient operation and maintenance of oil.

- Laboratory Analysis - The transmission and analysis time is long and the timeliness is poor; the sampling process may cause secondary contamination to the oil; the data presentation form is weak.

- Field Testing - It is necessary to purchase professional equipment and add professional testing personnel, which increases costs and management difficulties; the deep-seated causes of equipment failures behind the oil status cannot be analyzed.

- 5G Communications - The oil online monitoring product that supports 5G communication is unique and leading in the industry. It can be equipped with wired optical fiber, Ethernet, RS485, WiFi and other communication methods according to the scenario to meet the networking needs of multiple scenarios.

- Built-in Oil Pump - The product is innovative and unique, with its own oil pump, covering low-pressure oil circuit scenarios. It does not require an external oil pump device, reduces construction difficulty, reduces the length of the sampling loop, and reduces the risk of oil leakage at the interface.

- State Controllable - The oil pump status is controllable, and the return oil flow rate can be adjusted according to the oil condition. The system has high stability and strong anti-interference ability.

- Accurate Monitoring - Strong power can reduce system pressure loss, more complete oil sampling and more accurate detection results.

- Safe and Reliable - The explosion-proof version and coal safety version adopt the "oil" and "electricity" separation dual shell mode, and have dual working modes of sensor and monitor; the sensor shell is equipped with flame arrester, current limiting valve and drain valve to ensure safety.

- Indicator Visualization - It can detect key parameters such as metal wear particles, moisture, viscosity, temperature, density, dielectric constant, etc. in the oil, visualize the data, and comprehensively display the multi-dimensional monitoring index card.

- Unified Management - It can be connected to the predictive maintenance system and supports the access of various process data of equipment to comprehensively evaluate the equipment status.

- New National Standard Certification - The solution incorporates innovative online monitoring products for mining oils and liquids, which meet the new national standards for the industry and are reliable.

Class C/Non-critical Equipment

Class C equipment is generally unimportant equipment in industry production. There are a large number of them and they are scattered. Traditional equipment maintenance is usually based on fixed cycles or regular inspections. The inspection workload is large and the efficiency is low. There is a risk of over-maintenance or failure to detect faults in time. If a fault occurs, it may have a certain impact on the production process, but the value of high-precision online monitoring is not high. Ronds's intelligent monitoring solution for Class C equipment replaces manual inspections through low-cost, wide-coverage online monitoring methods, realizes intelligent inspections of Class C equipment, and reduces maintenance costs and human resource investment.

- Difficulty in Inspection - Class C equipment is scattered and huge in number, making daily inspection difficult.

- High-Precision Monitoring Is Not Valuable - Class C equipment does not affect overall production, and high-precision online monitoring is not valuable.

- Many False Alarms - Traditional Class C sensors on the market are unable to perform fault waveform analysis and have many false alarms.

- Online Monitoring Is Expensive - The Class C equipment monitoring solutions on the market have a narrow coverage, high initial investment, high subsequent maintenance costs, and low cost-effectiveness.

- Intelligent Online Monitoring - Use sensors for online monitoring to replace manual inspections and reduce the inspection load on personnel.

- Long Distance Coverage- Sensor LoRa communication, long distance coverage, unobstructed communication up to 2KM.

- Reduce Project Costs - It can carry over 200 sensors, further reducing project costs.

- Low Maintenance Costs - Large capacity battery, standard strategy can be used for 3 years, low maintenance cost.

CBM Systems Benefits

Get best cost and benefit from machinery full life cycle management.

Make remote condition monitoring.

Reduce unplanned shutdown, improve production efficiency, prevent economic lose or unexpected disaster caused by unplanned shutdown

Guide maintenance plan, optimize spare parts purchasing and storage

Facilitate the intelligent transformation of operation and maintenance

DOWNDLOAD PDF RONDS PREDICTIVE MAINTENANCE SOLUTION

Fill up a details to download the PDF Files:

Customer Support

For more information about our Wireless Condition Monitoring System, get in touch with a member of the team, call us now on Penang Office 04-399 7522 or Petaling Jaya 03-7804 7522.