High-precision color measurement: How it works

Sciengate Automation offers Micro‑Epsilon’s colorSENSOR platform delivers industry-grade color inspection solutions—speedy, accurate, and highly configurable. Whether you’re handling reflective plastics, transparent materials, or metal parts, there’s a tailored sensor setup to ensure flawless process control and zero color-based defects.

Introduction

Quality control today demands precision, speed, and flexibility. Whether you're evaluating pill color consistency, glass tint in flat‑glass manufacturing, or sorting plastic bottle caps, detecting exact color shades is essential. This is where Micro‑Epsilon’s colorSENSOR family shines. Micro‑Epsilon’s colorSENSOR systems are engineered for relative color measurement: a controller compares a product’s color against a pre-taught reference. The result is a clear good/bad signal, not just raw data.

These systems consist of:

-

A CFO controller (e.g. CFO100/200/250) that performs the evaluation.

-

Sensor heads (CFS models) connected via fiber optics, tailored to different surface types or target objects.

Key Advantages of CFO Controllers

-

Ultra-high color accuracy: ΔE ≤ 0.3 ensures extremely precise color differentiation

-

Blazing-fast performance: Evaluation up to 30 kHz, with data output via Lab or XYZ up to 500 Hz.

-

Large color memory: CFO200 stores 320+ colors across 254 groups, ideal for handling multiple batches or variants.

-

Intuitive setup: A web-based interface allows teaching colors, adjusting tolerances, and monitoring values without additional software.

-

Customize & calibrate: Customers can request tailored calibration for matched Lab values across systems (ΔE<1)

How It Works

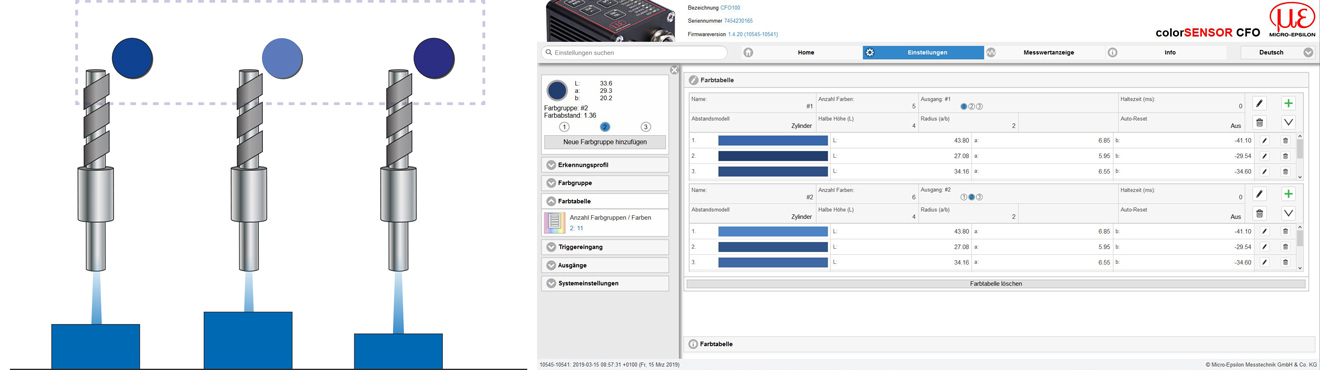

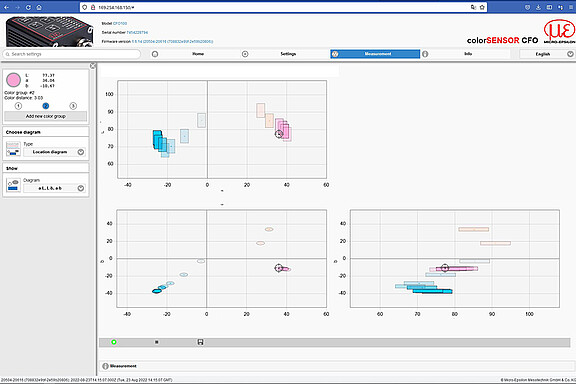

The integrated, intuitive web interface simplifies configuration of the CFO system. The sensor is connected to a PC via an Ethernet interface. The web interface features measurement value display, set up and configuration of e.g. exposure and measurement frequency. Furthermore, the sensor can be adapted to suit different color groups and tolerance space for each color.

The colorSENSOR CFO performs an internal evaluation based on taught-in color values at up to 30 kHz and outputs the result via digital switching signals. In addition, the raw data can be transmitted directly to a PLC or machine system in Lab or XYZ at up to 500 Hz via a UDP, RS232 or USB interface. This can be done continuously or only on demand. Corresponding edge or level triggers also control for how long or how many measured values are output.

The multi-teach function allows for geometry-dependent color variants to be taught in color groups. Since the detected colors vary with different distances between sensor and measuring object, these color variants can easily be taught into a color group. Individual color groups can be created for different color shades.

In order to improve the recognition performance and to reduce deviating measurement values between several sensors for a certain configuration, customers can request a customer-specific calibration for the colorSENSOR CFO200. Therefore, the sensor and the controller are calibrated to the customer-specific reference target in the measurement arrangement required. A measurement deviation of Delta E < 1 between the individual systems can be achieved. Due to the calibration, the sensors are exchangeable and measure colors which have almost the same Lab values.

Multiple interfaces for easy integration

Applications

Color measurement of car attachments

Color recognition for seams in automotive interiors

Color detection of kitchen fronts

Marking detection on cosmetics bottles

Technical Sales Support

For more information about our automation and Micro-Epsilon measurement sensors, get in touch with a member of the team, call us now on Penang Office 04-399 7522 or Petaling Jaya 03-7804 7522.